One of the best parts about working at Iron Age Office is the collaboration of creative individuals throughout the design process of a new product. That idea can be sparked internally or externally. Sometimes, a client has an idea of what they want, and we work hard to exceed their expectations. Join us as we unveil the secrets behind the creation of our extraordinary furniture.

Iron Age Office owes its humble beginnings to the vision of our founder and CEO, Sean Dineen. In the early days, Sean would take client descriptions and sketch them by hand, sparking the imaginations of our skilled welders who would bring these visions to life. This process has changed drastically with a bigger team, better technology, and the continued growth of Iron Age Office.

BRAINSTORMING

When purchasing with Iron Age Office, you will first speak with our interior designers, Gianna and Bianca. Together, they embark on a collaborative journey with you, delving into the depths of your imagination and working to turn dreams into reality. With your ideas and inspiration, they sketch a design fitting with Iron Age’s philosophy of sophisticated industrial office furniture.

MAKING IT WORK

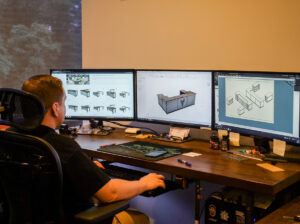

Once the idea is conceptualized, it’s sent to our lead draftsman, Steven. He tweaks and engineers the design in a CAD development software called Inventor. Every detail from weight distribution to structural integrity is meticulously modified until a computerized rendering of the design emerges, capturing the essence of your vision.

PROTOTYPE CREATION

After the computer design stage is complete, a blueprint of the prototype is provided to our welders and wood craftsmen, and they begin the build process. Once the product is perfected, it’s sent off to the client. (Psst.. here’s what our delivery process looks like.) There have been a few rare cases where multiple prototypes have been required until the product is up to Iron Age standards. In case that was too subtle, ONLY top quality, perfectly precise, and durable furniture will leave our warehouse.

MADE TO ORDER FROM THE BEST MATERIALS

All of our furniture is made by our craftsmen onsite in Kennesaw, GA with materials meant to stand the test of time. The steel we use, renowned for its reliability, has been instrumental in constructing some of the world’s tallest skyscrapers. Meanwhile, maple wood, chosen for its exceptional core integrity and strength, has graced the floors of bowling alleys for decades. One of our desks survived a category 5 hurricane with only minor cosmetic damage! By the end of the creation process, we promise you will have a piece of furniture that surpasses your customized expectations and ignites excitement for your work.